Keep fat where it belongs — in your profit!

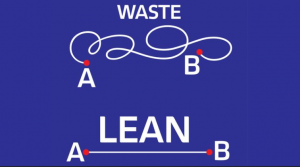

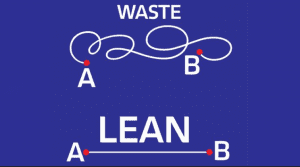

Waste reduction is an inescapable part of Lean. Last week’s blog described how to implement a continuous improvement process into your workflow. It makes sense from the efficiency and cost-savings perspectives, but it could seem complicated when you’re on the outside looking in.

To get the benefits from Lean, you evaluate your processes but it isn’t as complicated or time-consuming as you think. Read on to discover the simple steps and get started.

- Identify inefficiencies – If it’s unclear where the biggest time wasters are in your process, ask your staff and make a list of these areas.

- Double-check – Walk someone who doesn’t know the process through it and write down their thoughts.

- Engage your peers – Ask the co-workers who are downstream and upstream from you to evaluate the process.

- Write it down – When you first document processes, you detect gaps and inefficiencies. Establish procedures to stop employees from introducing waste through extra steps.

- Ask coworkers to evaluate – Your written steps should be reviewed by your downstream and upstream team, as well as any of your staff who are touched by the process.

Your WISP will become more efficient, but you will also become more cohesive as a collaborative team. Get even greater benefits and align yourself with vendors that embrace Lean concepts.

Lean the company and fatten the profits!